Subject Guide

Mountain West

Malachite’s Big Hole

Flint Caps:

It is very difficult to tightly secure a gunflint in the flint vise of the lock hammer without some form of padding. Cloth was not found to be satisfactory because eventually it would catch fire. Padding was most often a piece of leather, but often a thin sheet of lead would serve the purpose as well. A lead ball could be hammered into a thin sheet for this purpose, or such lead grips could be purposely manufactured in which case they were called flint caps.

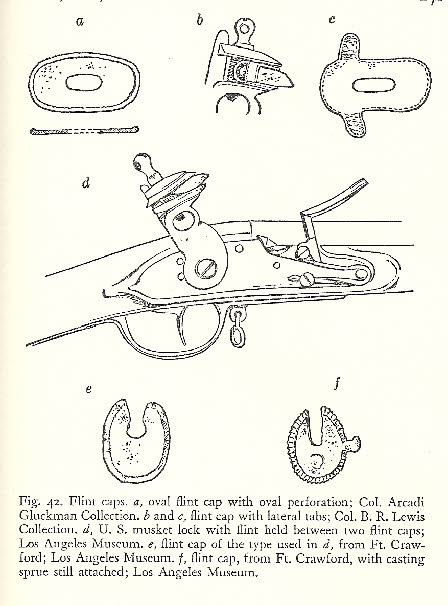

Flint caps could be either two separate disks, one each to be placed above and below the gunflint in the hammer, or a single elongate oval which was folded around the flint before it was placed in the vise. Both types of flint caps would have a cutout or perforation to accommodate the vice screw. The size of the cap would vary depending on the flint size. A flint cap for a military rifle is described as being 1/32nd of an inch thick with a slightly thicker rim (Russell, 1957, page 240). Some flint caps also have tabs that could be folded down around the sides of the gun flint. The figure below, (from Russell, 1957 page 241), illustrates several different types of flint caps and their use.

Sprues remaining on some caps show that purposely manufactured caps were poured, not stamped.

Records indicate that large numbers of flint caps were ordered for the military. Procurement records for the Springfield Armory indicate that a total of 280,000 flint caps were acquired in the period 1829-1844 for this facility alone. After 1844 there are no records indicating additional purchases by the military of flint caps. (Russell, 1957 page 240)

For more information regarding flint caps see:

Russell, Carl P., Guns on the Early Frontiers. Published by the University of California Press, Berkeley and Los Angeles 1957.