Subject Guide

Mountain West

Malachite’s Big Hole

Steel Traps:

Because the Mountain Men were so transient, it was important that their traps be

as light as possible, without sacrificing either durability or effectiveness. Trap

designs were numerous, and the well designed trap would fold in on itself for transport.

Most traps weighed about five pounds, however traps as light as one and three-quarters

pounds were used. Generally the traps used beaver had two powerful springs mounted

at the hinges to snap shut the jaws, although single spring traps were manufactured

and some bear traps had as many as six springs. The six-spring bear-traps were so

powerful, that special screw clamps were required to depress the springs when setting

the trap.

numerous, and the well designed trap would fold in on itself for transport.

Most traps weighed about five pounds, however traps as light as one and three-quarters

pounds were used. Generally the traps used beaver had two powerful springs mounted

at the hinges to snap shut the jaws, although single spring traps were manufactured

and some bear traps had as many as six springs. The six-spring bear-traps were so

powerful, that special screw clamps were required to depress the springs when setting

the trap.

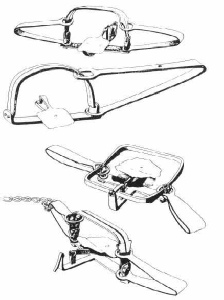

The image to the right shows various trap designs (from Russell, Firearms, Traps and Tools of the Mountain Men)

Trap prices varied depending on size and make. In 1822 both British and American beaver traps were selling for $3.00 a piece, an expensive item at a time when gold was worth $20 an ounce. Traps, spare springs and other trap parts were common items on inventories of goods shipped to the annual rendezvous.

The image below is by John Audubon, drawn about 1844, depicting a Canadian Otter in a double spring trap. Except for minor details this trap is almost identical to some modern traps.

Trap springs may well have provided source material for emergency fabrication of knives in the mountains. According to one contemporary source who reported that those (trapper/hunters originally based out of Taos and moved on to settle in California) who owned vineyards found that the steel springs of the beaver traps "had just the right shape to be forged into pruning knives," (source Foster, "Pioneers of Los Angeles," Historical Society of Southern California, 1887, 35.) It’s my opinion that it is not likely that only mountain men turned vintners noticed that trap springs could be used for knife making material.